SEPTON™

Kuraray Elastomers / SEPTON™

SEPTON™

A high-performance thermoplastic rubber.

About SEPTON™

SEPTON™ is a styrenic thermoplastic elastomer developed by Kuraray. It has been utilized in many TPE compounds. It can be processed in various forms, covering various applications, including compounds, polymer modification, adhesives, flexible PVC substitutes, and vibration-damping products.

For years, SEPTON™ has been setting benchmarks and transforming our perception of quality. SEPTON™ ignites innovation, consistently surpasses industry standards, and has become a staple in diverse domains.

Industries Used

SEPTON™ is used in different TPE compounds and can be processed in various forms, including soft-touch grips, consumer goods, and automotive components. Specific SEPTON™ grades are certified and used in consumer goods, mobility, medical and oil modification applications.

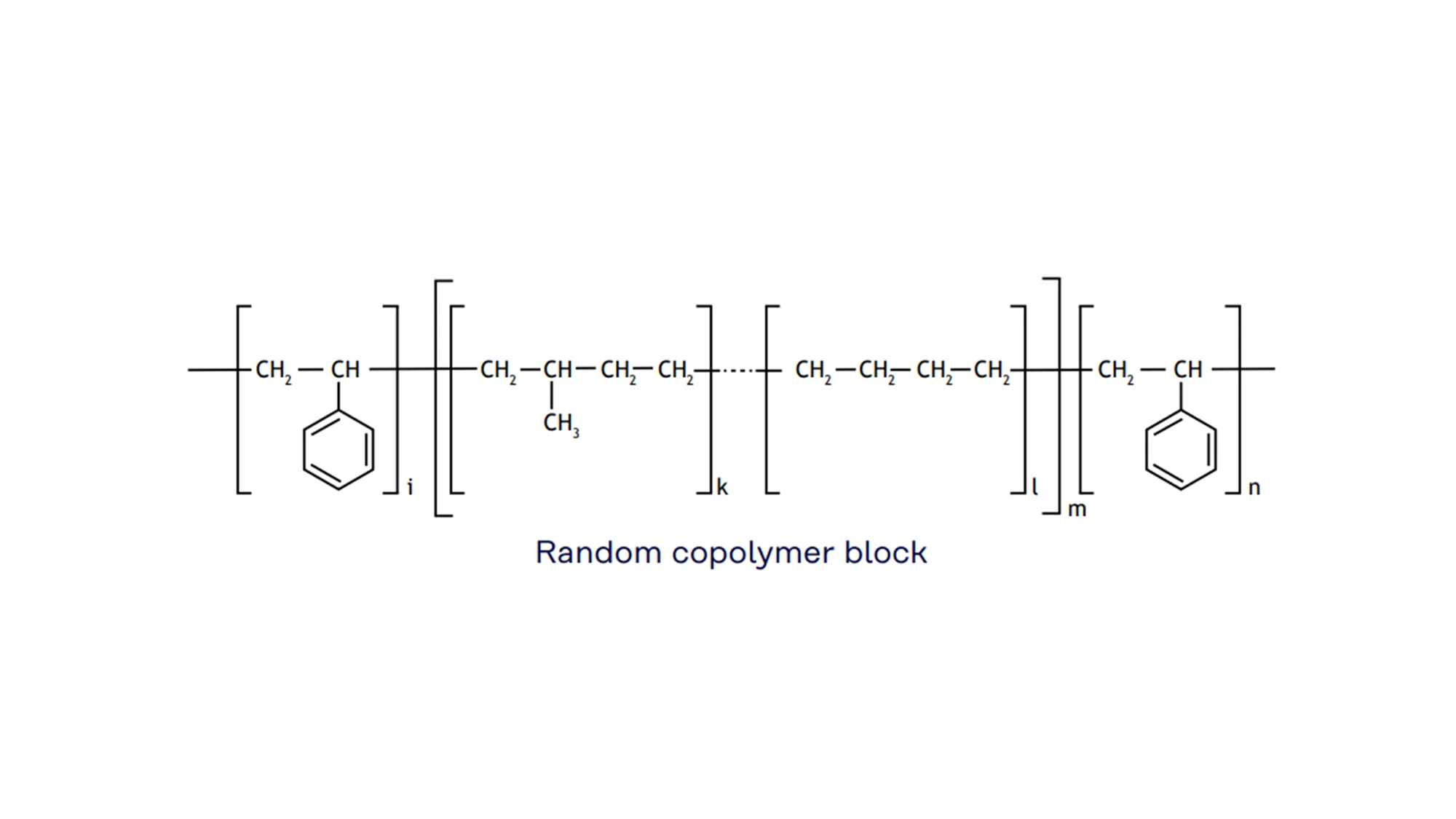

The Hydrogenated Styrenic Block Copolymers (HSBCs) consist of a hydrogenated diene soft block and styrene-based hard blocks. HSBCs display a rubbery elasticity because the hard block serves as a crosslinking spot below the glass transition temperature of polystyrene, while the soft block imparts elasticity. The process of hydrogenation generates heat and weather resistance.

Elevating vehicular components for optimal performance.

Crafting cutting-edge medical devices with high durability.

Ensuring athletes’ peak performance with top-tier gear.

Molding everyday products that offers great quality.

Standard grades and properties

| Grade | Type | Styrene content | MFR | Solution viscosity (Toluene Solution 30ºC) | Physical form | Hardness (Type A) | |||

| 230ºC, 2.16 kg (g/10min) | 200ºC, 10kg (g/10min) | 5wt% (mPa•s) | 10wt% (mPa•s) | 15wt% (mPa•s) | |||||

| 1020 | SEP | 36 | – | 1.8 | – | 42 | – | Powder | 70 |

| 2002 | SEPS | 30 | 70 | 100 | – | – | 25 | Pellet | 80 |

| 2004F | SEPS | 18 | 5 | – | – | – | 145 | Pellet | 67 |

| 2005 | SEPS | 20 | No flow | No flow | 40 | 1700 | – | Crumbs | – |

| 2006 | SEPS | 35 | No flow | No flow | 27 | 1220 | – | Crumbs | – |

| 2063 | SEPS | 13 | 7 | 22 | – | 29 | 140 | Pellet | 36 |

| 2104 | SEPS | 65 | 0.4 | 22 | – | – | 23 | Pellet | 98 |

| 4033 | SEEPS | 30 | <0.1 | <0.1 | – | 50 | 390 | Powder | 76 |

| 4044 | SEEPS | 32 | No flow | No flow | 22 | 460 | – | Powder | – |

| 4055 | SEEPS | 30 | No flow | No flow | 90 | 5800 | – | Powder | – |

| 4077 | SEEPS | 30 | No flow | No flow | 300 | – | – | Powder | – |

| 4099 | SEEPS | 30 | No flow | No flow | 670 | – | – | Powder | – |

Get Your Free Brochure Download Now!

Applications

TPE compounds

Adhesives, coatings, and sealants

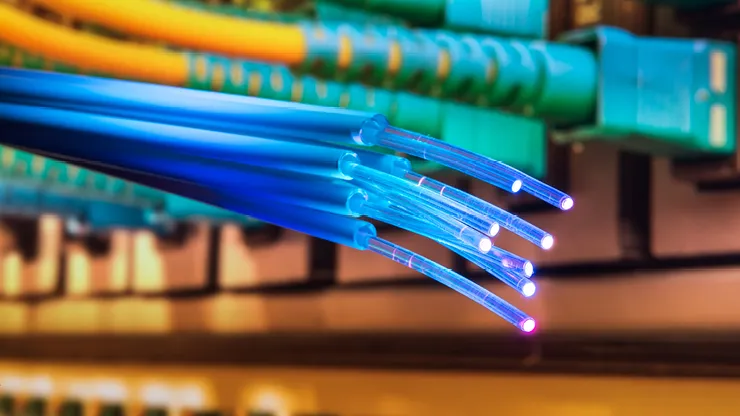

Wires, cable skin material

Fabrics, nonwoven materials

Automotive parts

Plastics modifiers, compatibilizers

Medical parts

Toys, sporting goods

Elastic film

Soft touch applications, grips

Gels

Packaging materials

TPE Compound for cables

Footwear Compound

Softtouch Grip Compound

Orthopedic Gel

Key Characteristics

- High Elasticity: SEPTON™ is notably stretchy and can return to its original shape after being deformed, making it suitable for products that need to flex without breaking or warping.

- High Strength: The material is robust, meaning it can withstand significant stress and pressure without deteriorating, ensuring durability in various applications.

- Weather Resistance: SEPTON™ can endure various weather conditions, such as sun, rain, and wind, without losing its quality, making it ideal for outdoor and automotive applications.

- Low Temperature Properties: It maintains its properties even in chilly conditions, ensuring functionality and reliability in cold environments without becoming brittle.

- Chemical Resistance (acid, alkali, alcohol): The material resists damage from various chemicals like acids, alkalis, and alcohols, preserving its integrity in diverse environments.

- Heat Aging Resistance: SEPTON™ can withstand prolonged exposure to heat without degrading, ensuring longevity and consistent performance in high-temperature applications.

- Electrical Property (insulation): It acts as an insulator, preventing the flow of electrical current, which is crucial for ensuring safety in electrical applications.

- Recyclable: SEPTON™ can be recycled, contributing to environmental sustainability by reducing waste and enabling the reuse of materials in new products.

Related Products

Browse our wide range of innovative products with diverse applications.