KURARITY™

Elastomers / KURARITY™

KURARITY™

A flexible without typical acrylic odour block copolymer known for its clear appearance and weather resistance.

About KURARITY™

KURARITY™ is a new series of acrylic block copolymers made using Kuraray’s specialised anionic living polymerisation technology by uniting diverse (meth)acrylates into AB or ABA-type block copolymers. The structure grants KURARITY™ a range of properties like clear visibility, weather durability, self-sticking, and compatibility with other polar materials. It uses adhesives, moulded items, light guides, and plastic modifiers and additives.

Industries Used

KURARITY™ showcases properties like clear visibility, weather durability, self-sticking, and compatibility with polar materials due to its unique structure. The acrylic block copolymer is versatile, finding uses in various applications like adhesives, coatings, sealants, and 3D printing, including light guides in mobility and home appliances. It can modify polar plastics as an additive and is suitable for injection and extrusion applications.

KURARITY™ provides strong, flexible adhesives for durable surface protection films and industrial tapes.

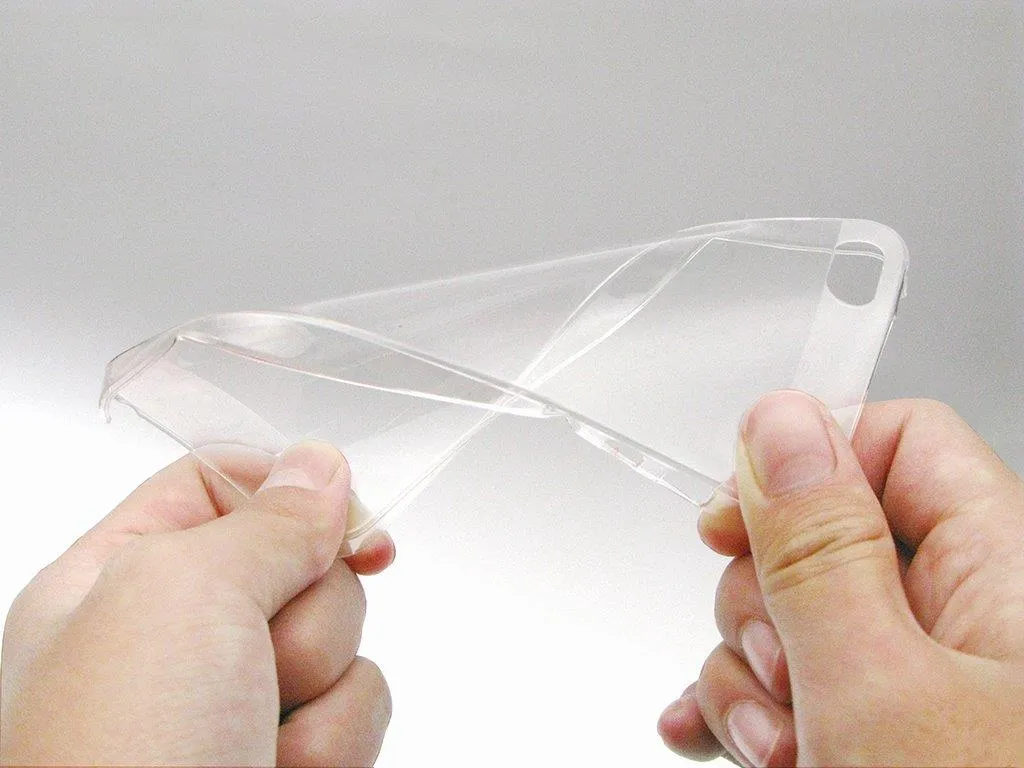

Offering clarity and resilience, KURARITY™ excels in creating durable moulded parts.

Enhances polar plastics’ properties, improving the quality of adhesives, inks, and paints.

Great clarity and barrier properties ensure optimal product protection and presentation.

Get Your Free Brochure Download Now!

Standard grades and properties

| Measurement method/conditions | Unit | LA3320 | LA2330 | LA2250 | LA2270 | LA4285 | |

|---|---|---|---|---|---|---|---|

| Hardness | ISO 7619-1 (Type A) | (-) | 13 | 32 | 65 | 71 | 95 |

| ISO 7619-1(Type D) | (-) | < 5 | < 5 | 18 | 23 | 46 | |

| Specific gravity | ISO 1183 | (-) | 1.06 | 1.08 | 1.08 | 1.10 | 1.11 |

| MFR | ISO 1133 [190ºC 2.16kg] | (g/10min) | 6.2 | 3.7 | 25 | 4.4 | 1.5 |

| ISO 1133 [230ºC 2.16kg] | (g/10min) | 63 | 42 | 330 | 80 | 31 | |

| Modulus at 100% | ISO 37 | (MPa) | 0.4 | 0.3 | 3.7 | 9.0 | 19 |

| Tensile strength | ISO 37 | (MPa) | 3.6 | 7.2 | 9.0 | 12 | 19 |

| ISO 527-2 | (MPa) | – | – | – | – | 19 | |

| Tensile elongation | ISO 37 | ()%) | 540 | 490 | 380 | 149 | 140 |

| ISO 527-2 | (%) | – | – | – | – | 90 | |

| Young’s modulus in flexure | ISO 178 | (MPa) | – | – | – | – | 650 |

| Charpy impact | ISO 179-1 (Notched: 1eA) | (kJ/m2) | NB | NB | NB | NB | 28 |

| Transmittance | ISO 13468-1 [3mm thick] | (%) | 92 | 91< | 91< | 93 | 91< |

| Haze | ISO 14782 [3mm thick] | (%) | 2.0-6.01 | 2.0-6.01 | 2.0-6.01 | < 1.0 | < 2.0 |

| Suitable applications | Adhesive | ○ | ○ | ○ | |||

| Molding material | ○2 | ○2 | ○ | ||||

| Modifier and additive | ○2 | ○2 | ○2 | ○2 | ○ |

Notes 1: The haze value is normally worse due to the anti-blocking agents dusted onto pellets.

2: These grades can block or bridge while feeding into the extruder.

The above figures should be regarded as guide values only and not as binding minimum values. (Tested by Kuraray)

Applications

Adhesive

Adhesives for surface protection films, industrial tapes, and labels. Spray adhesives, hot melts, solvent-based adhesives.

Moulded parts

Automotive interior lighting, light guides, illuminations, smartphone cases, automotive interior components.

Plastics modifier and additive

For polar plastics (PMMA, ABS, PLA, AS, PVC, TPU, PVDF, PC, PBT, POM, etc.), adhesives, inks, paints.

Light Guiding Rods

for high end automotive applications.

Key Characteristics

- Self–adhesive: KURARITY™ effortlessly adhere to various surfaces without additional adhesives, simplifying applications and ensuring reliable bonding in diverse environments.

- Functional Group/Acid–Free: The absence of functional groups or acids in KURARITY™ ensures a stable and non-reactive profile, enhancing durability and compatibility with various materials and environments.

- Excellent Clarity: KURARITY™ ensures high transparency, providing aesthetically appealing and pure materials that can be utilised in applications where visual clarity is paramount.

- Extremely Low Residual Monomers or Oligomers: With minimal residual monomers or oligomers, KURARITY™ ensure a cleaner and more stable composition, reducing the risk of unwanted reactions and maintaining the integrity of the material.

- Ultimately Less Odor: The minimal odour of KURARITY™ ensures they are suitable for applications where a neutral smell is crucial, providing comfort and avoiding unpleasant sensory experiences.

- Excellent Weatherability and No Concerns About Hydrolysis Degradation: KURARITY™ is designed to withstand various weather conditions and resist hydrolysis degradation, ensuring long-lasting performance and reliability in outdoor and challenging environments.

- High-Gloss, Comparable with PMMA: KURARITY™ exhibit a high-gloss finish, akin to PMMA, enhancing the visual appeal and providing a premium, shiny appearance across various applications.

- Excellent Flexibility, Without Plasticizers: Offering robust flexibility without plasticisers, KURARITY™ maintain their flexibility and strength, ensuring durability and adaptability in various applications.

- Excellent Injection/Extrusion Moldability: KURARITY™ can be seamlessly moulded using injection or extrusion methods, offering manufacturing versatility and facilitating diverse design possibilities.

- Good Compatibility with Polar Plastics: KURARITY™ ensure easy integration in various manufacturing processes and applications, enhancing material cohesion and product performance.

Related Products

Browse our wide range of innovative products with diverse applications.