EVAL™

Eval™ / EVAL™

EVAL™ - World’s First EVOH Resin

Pioneering gas barrier technology to protect product freshness, safety, and extended shelf life.

About EVAL™

Since its inception in 1972, Kuraray has been the leader in gas barrier technology, pioneering the production and enhancement of ethylene vinyl alcohol copolymer (EVOH). Under the brand name EVAL™, Kuraray boasts diverse grade range of EVOH resin globally.

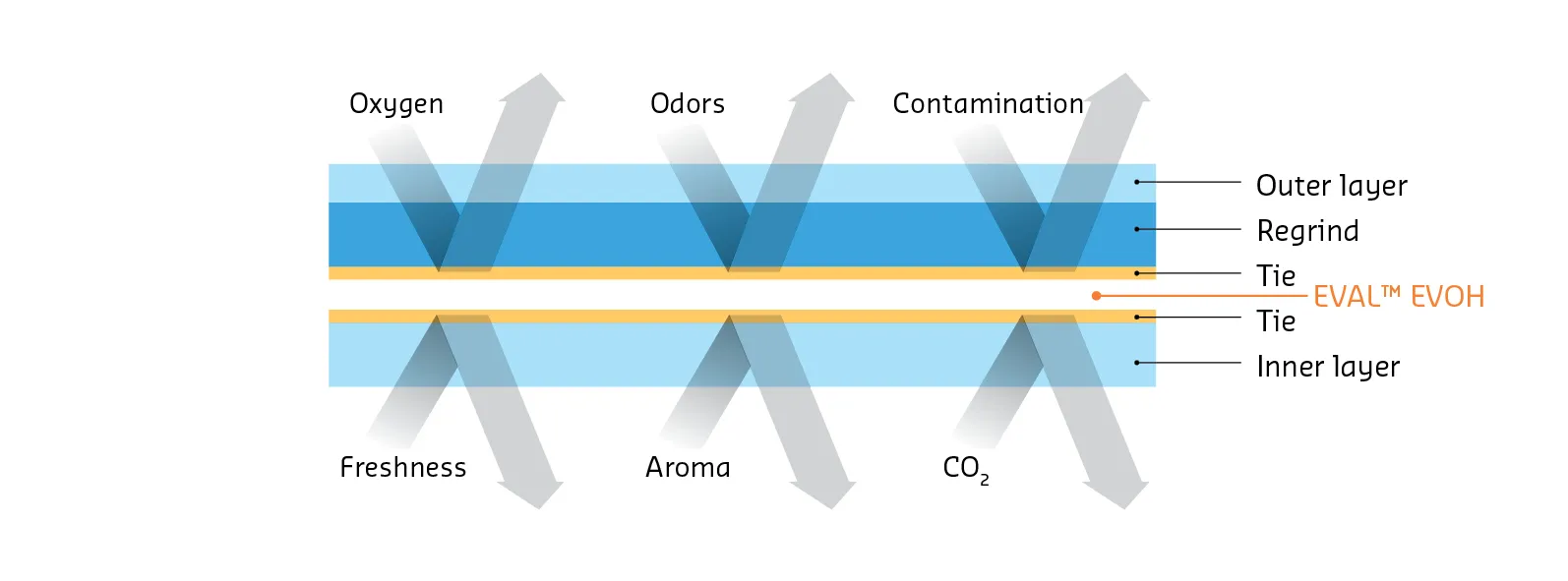

A mere 1mm thickness of EVAL™ equates to the gas barrier capabilities of a 10-meter wall made of LDPE. Even a thin layer of EVAL™ can significantly enhance the barrier properties of composite layers. Incorporating EVAL™ in multilayered designs presents a transparent, lightweight, and robust alternative to traditional materials like glass and metal.

Industries Used

EVAL™ finds its application in various sectors, from food packaging to automotive fuel tanks and medical containers to agricultural films. It’s a versatile solution tailored for diverse industry needs.

The dual-directional barrier function of EVAL™ prevents harmful oxygen and contaminants from reaching sensitive products and also acts as a sealant, preserving the aroma and value within. The dual functionality makes EVAL™ an ideal choice for sectors that demand high-quality protection, such as food, medical, pharmaceutical, and healthcare packaging.

With EVAL™, food stays fresh and protected. It’s a top choice for packaging a wide variety of edibles.

For vehicles, EVAL™ ensures fuel tanks don’t leak, contributing to long-lasting performance and safety.

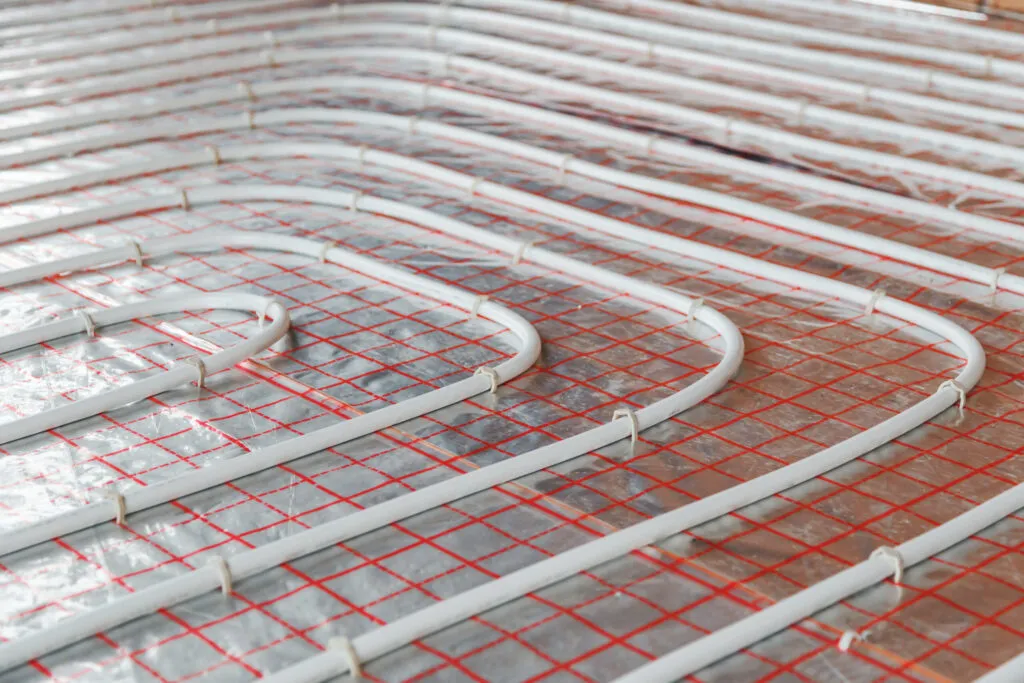

Appropriate for use in industrial piping systems and versatile building & construction barriers.

EVAL™ safeguards agrochemicals to enhance soil fumigation, ensuring quality and safety at every step.

Get Your Free Brochure Download Now!

Applications

Food packaging materials

Medical packaging materials

Automotive plastic fuel tanks

Under-floor heating pipes

Containers for agrochemicals

Soil fumigating films

Vacuum insulation panels

Districted energy pipes

Standard grades and properties

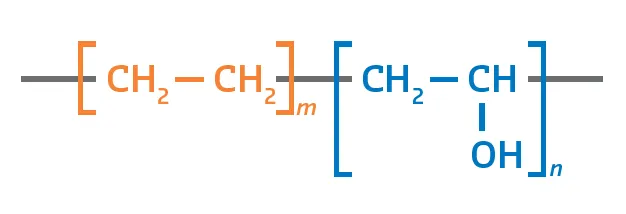

Molecular structure of EVAL™ resin – EVAL™ is a random copolymer of ethylene and vinyl alcohol. It’s a crystalline polymer that has a molecular structure, as represented by the formula on the right. EVAL™ resin combines the humidity resistance and easy processing of ethylene with the exceptional gas barrier and resistance to organic solvents of vinyl alcohol.

Available types of EVAL™ resin – We have developed different types of EVAL™ resin. Each type offers different useful characteristics, based on the ethylene mol% content.

EVAL™ M type

This type has the lowest ethylene content available; it provides the highest barrier for automotive and flexible applications.

EVAL™ L type

This type has a very low ethylene content and is suitable as an ultra-high barrier in flexible, bottle and sheet applications.

EVAL™ F type

This type offers superior barrier performance with long-term process stability and is widely used as the standard grade for flexible, automotive, bottle and tube applications. Specific versions exist for coating and pipe applications.

EVAL™ J Type

This type offers superior thermoforming performances and can be used for deep-draw or sensitive sheet-based applications.

EVAL™ H type

This type combines high-barrier properties to long-term stability and thermoformability. The higher ethylene content allows easier processing and longer running times on older co-extrusion equipment, especially for blown flexible structures.

EVAL™ E type

This type has a higher ethylene content that allows for greater flexibility and even easier processing.

EVAL™ G type

This type has the highest ethylene content, making it the best candidate among standard types of EVAL™ types for stretch and shrink film applications.

| Grade | Ethylene content (mol%) | Density1 (g/cm3) | MFR2 (g/10 min) | Melting point (ºC) | Glass transition point3 (ºC) | Oxygen transmission rate4 (cm3・20μm/m3・day・atm) | Applications |

|---|---|---|---|---|---|---|---|

| L171B | 27 | 1.21 | 4.05 | 190 | 63 | 0.1 | High barriers |

| F101B | 32 | 1.19 | 1.6 | 183 | 60 | 0.3 | Fuel tanks, bottles, tubes |

| F171B | 32 | 1.19 | 1.6 | 183 | 60 | 0.3 | Bottles, sheets, film, tubes |

| H171B | 38 | 1.17 | 1.7 | 172 | 56 | 0.7 | Bottles, sheets, film, tubes |

| E105B | 44 | 1.14 | 5.5 | 165 | 53 | 1.9 | Sheets, film, tubes |

| G156B | 48 | 1.12 | 6.4 | 157 | 50 | 3.7 | Stretch film, shrink film |

1. 20ºC 2. 190ºC, 2,160 g 3. Dry 4. 20ºC×65%RH, ISO14663-2 annex C 5. 210ºC, 2,160 g

Key Characteristics

- Superior Gas and Aroma Shielding: EVAL™ offers protection against gases and odors. In perspective, a 1 mm layer of EVAL™ provides the same barrier as a 10,000 mm layer of LDPE (a common plastic).

- Waste Reduction and Value Protection: It helps in minimizing waste and also maintain the quality of the products. By using EVAL™, you’re ensuring that the contents inside the packaging remain in their best condition, reducing the chances of them going to waste.

- Protection Against Chemicals and Vapors: Resilience of EVAL™ against various chemicals, oils, and even fuel vapors ensures that the packaging remains intact and the contents inside are unaffected.

- Compliance with Food Safety Standards: EVAL™ adheres to FDA and ensuring optimal protection and safe storage for food items. The commitment underscores its dedication to consumer health.

- Safe, Sustainable, and Eco-friendly: Green packaging solutions of EVAL™ are safe for consumers and recyclable, promoting environmental sustainability with every use.

Related Products

Check out other great products from Kuraray, made for many different use case.