GENESTAR™

Home / GENESTAR™

GENESTAR™

GENESTAR™ in that brand is a well-balanced long-chain polyphthalamide(PPA) that combines low water absorption and high mechanical properties over broad temperature range. High-performance polyamide plastic known for its moldability, strength, and heat resistance.

Discover GENESTAR™

GENESTAR™ , a polyamide engineering plastic made from a unique C9 monomer. It is a low water absorption and heat-resistant polyamide resin used in electrical and automotive parts industries. GENESTAR™ is a great alternative to materials like fluoropolymers, PPA (PA6T, PA4T, PA10T), PA46, PPS, and LCP.

Industries Used

GENESTAR™ is revolutionizing industries with its unparalleled properties. It’s the material of choice for electrical components, automotive electronics, and various vehicular parts, from sliding gears to fuel systems. Its adaptability extends to cooling systems, ensuring efficiency and durability.

Revolutionizing electronic components with its heat resistance and dimensional stability.

Provides enhanced safety and durability in vehicular components.

It functions as a heat-resistant resin which is ideal for LED lighting, LCD televisions, smartphones, and tablet.

Ensuring efficiency and durability in cooling components.

Get Your Free Brochure Download Now!

Automotive Applications

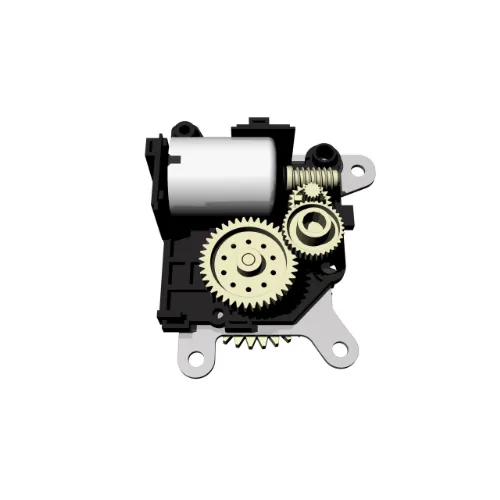

ETB Gear

Coolant Control Valve

EGR Valve Gear

HVAC Actuator (small)

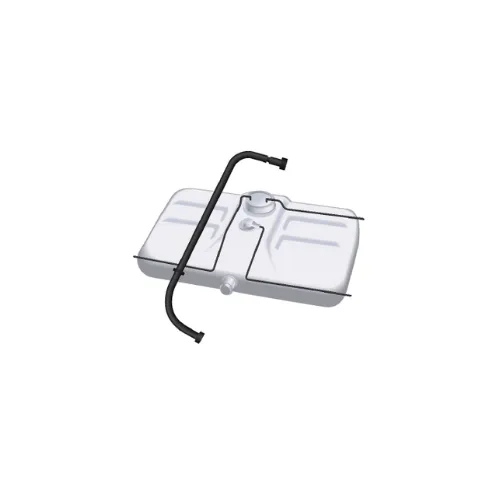

Fuel Tube

Thermostat Housing

Quick Connector

CAC Tank

Bearing Cage

Coolant Tube for Battery

Electrical Applications

ECU

Wire to Board Connector

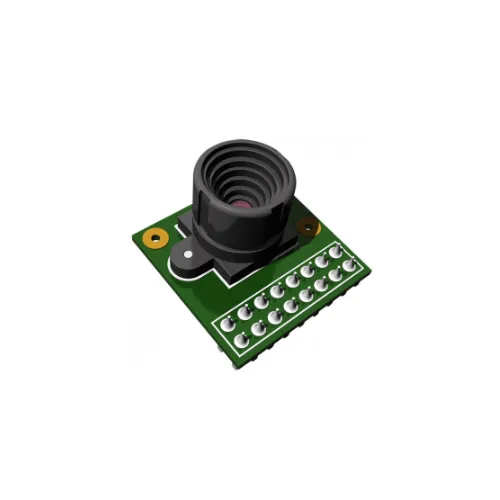

Camera Module

Automotive Camera

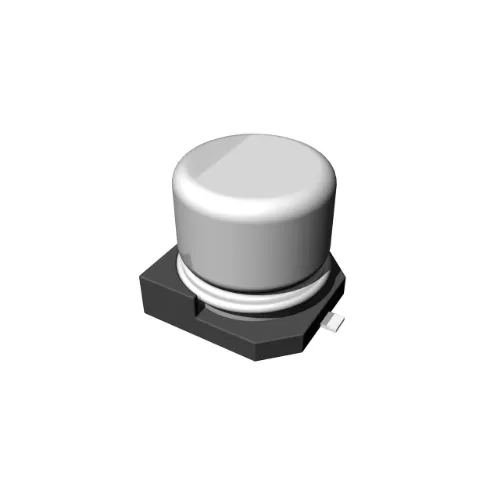

Condenser

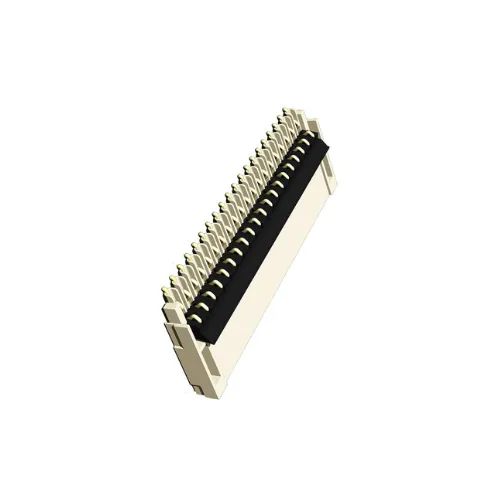

FPC Connector

HV Connector

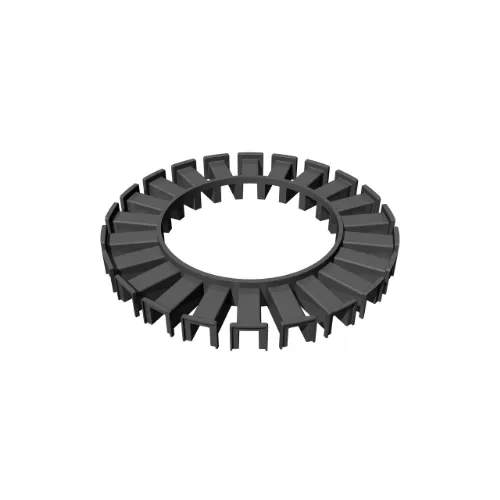

Motor Insulator

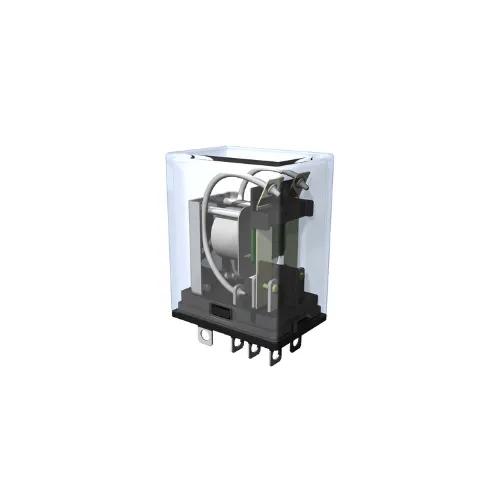

Relay

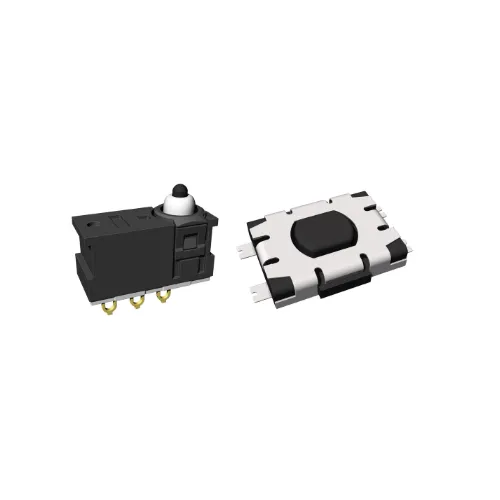

Switch

Key Characteristics of PA9T

- Low water absorption: The water absorption of polyamide is determined by amide group concentration. Because of the long chain diamine structure, it is low in amide group concentration and is difficult to absorb water.

- High heat resistance: PA9T is excellent in mechanical properties at high temperature. Since the glass transition temperature is 125℃, it can withstand sufficiently even in the automobile engine room which has been heated.

- Blister resistance: PA9T is suppresses the occurrence of blisters. It has been proven to suppress blistering even after reflow.

- Dimensional stability: Among polyamides, it boasts the highest level of dimensional stability. It can also be used for products where dimensional change becomes a problem.

- Moldability: Since PA9T is a homopolymer, it has been confirmed that it has less generation of gas during molding and is superior in moldability compared to general high heat-resistant polyamide products.

- Electrical characteristics: PA9T shows excellent tracking resistance. Therefore, it is suitable for USB type C and power semiconductor modules, as well as connectors that require high voltage.

- Chemical resistance: Even when immersed in various chemicals such as gasoline and engine oil which can not be avoided in automotive applications, it boasts high strength retention rate.

- Good coloration: PA9T is often used for in-vehicle connectors because coloring is good and color change is small after reflow.

Know More About GENESTAR™

Explore top-quality products from Kuraray designed for various needs.